GLASS

Furnace Audit

Systematic furnace audit results in several benefits. Continuous monitoring of decisive areas allows preventive correction of problematic situations before they become critical. It guarantees the stabilization of the glass quality and the furnace operability, with reduction of maintenance costs. For the detailed assessment of the condition of the furnaces, we offer, through our partner Glass Service, a wide range of resources.

VISUAL OBSERVATION OF REGENERATORS

Using common photographs combined with a patented method, we apply visual observation to determine the expected life of regenerators and to support decisions regarding possible repairs.

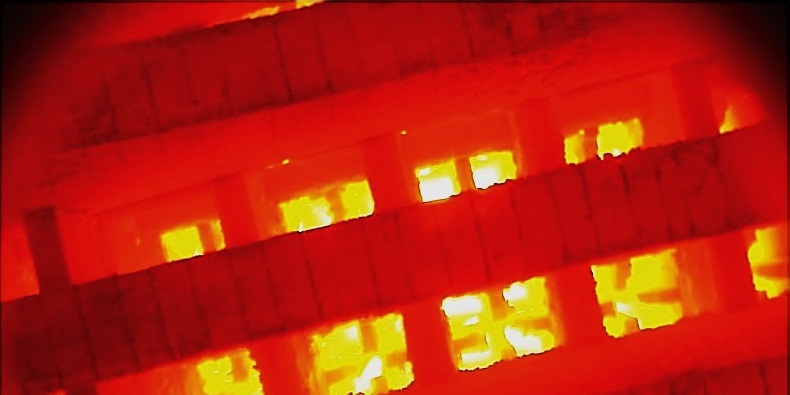

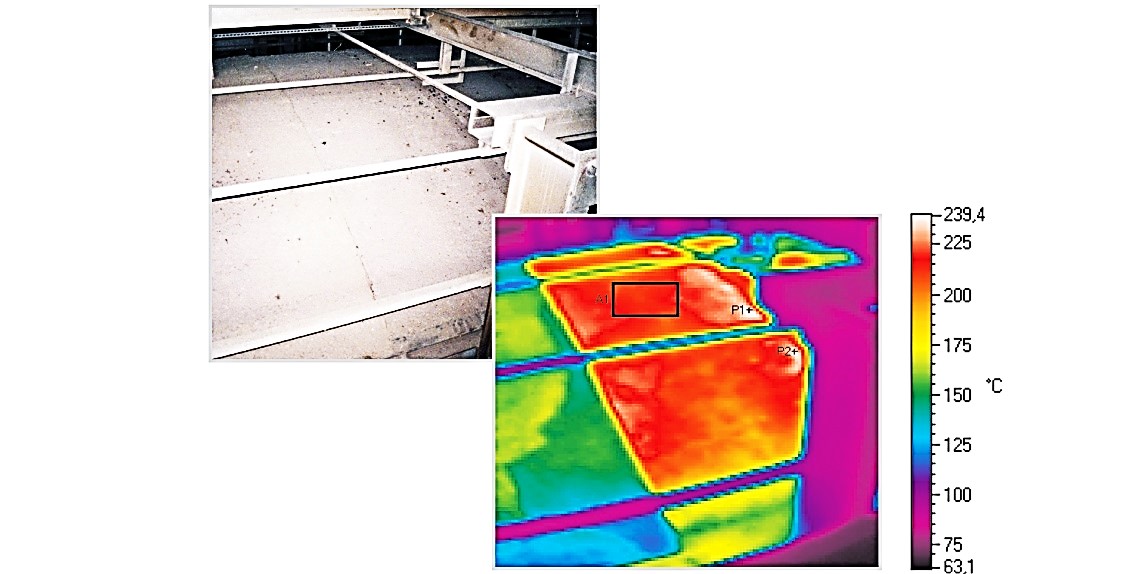

INFRARED INSPECTION OF EXTERNAL WALLS, CROWN ARCH AND BOTTOM

We perform the infrared evaluation on the accessible surfaces of the furnace. As a result, we identify the presence of possible critical areas of heat loss, hot spots, presenting recommendations for operational improvement and greater energy efficiency.

INTERIOR INSPECTION BY ENDOSCOPY

We prepare technical reports evaluating the condition of the furnace, with recommendations for repair and operational improvements. The analysis is made possible by performing comprehensive endoscopy of the ovens:

- Expansion joints of the crown arch, openings and presence of condensates

- Corrosion, spalling, material failure, brick displacement

- Sloped bricks, joints and corrosion

- Feeders, regenerators, recuperators

HEAT BALANCE

- Complete furnace heat balance

- Furnace temperature profiles

- Use of optical pyrometers

- Use of gas analysers (O2, CO and others)

- Evaluation of the furnace superstructure by endoscopy

- Evaluation of external temperatures with infrared cameras