Casting

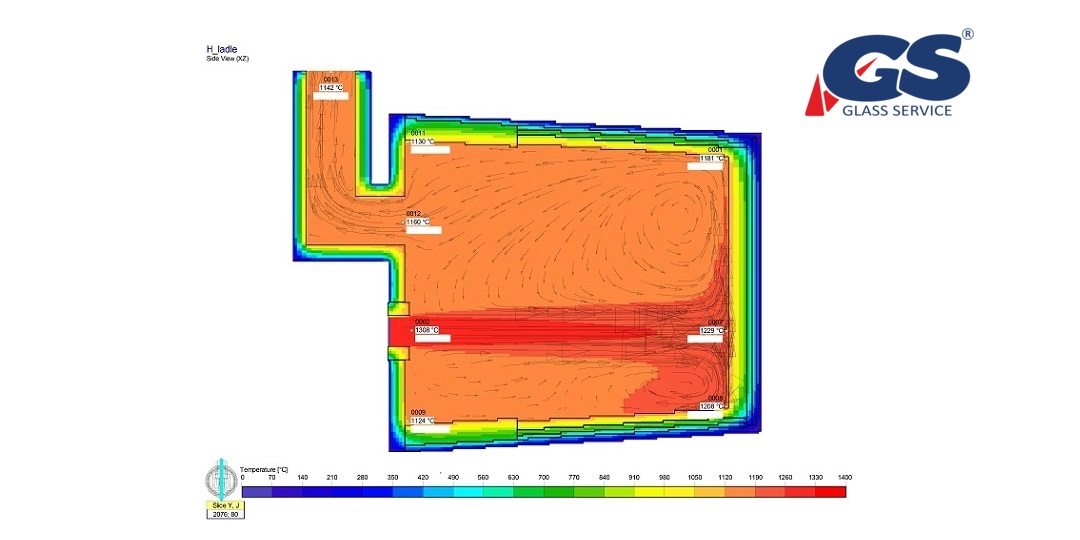

Thermal efficiency for the ladles cycle

We offer high efficiency thermal input for the start, partial stop and general refurbishment of a diversity of equipment at the casting area in steel mills: steel ladles, pig iron ladles, converters, pig iron mixers, valves, tundishes, RH systems, among others.

In the heating and drying operations, we use stations specially developed by our technology division, Æstus, to solve the main problems related to refractories and their thermal changes.

For the cleaning of ladles, we apply equipment and personnel specialized in operations with mobile system for monitored oxyfuel combustion.

We also conduct thermal studies of the entire ladles cycle, identifying and executing the best reheating curves for increased uptime and reduced fuel consumption.

Solutions for steel casting refractory

We act in the thermal conditions of steel casting for maximum performance of the refractories:

- Reduction of sequence breaks caused by low temperature

- Stability of tapping temperature

- Cut in heating and reheating times

- Increase in the refractory campaign

- Thermal uniformity and thermal soak

- Reduction of thermal shock

- Equalization of the temperature of ladle refractories at the bottom, baseboard and first rows with those at higher elevations

Featured

- We carried out the installation and operation of heating and reheating stations for 210-ton pig iron and steel ladles