PETROCHEMICAL

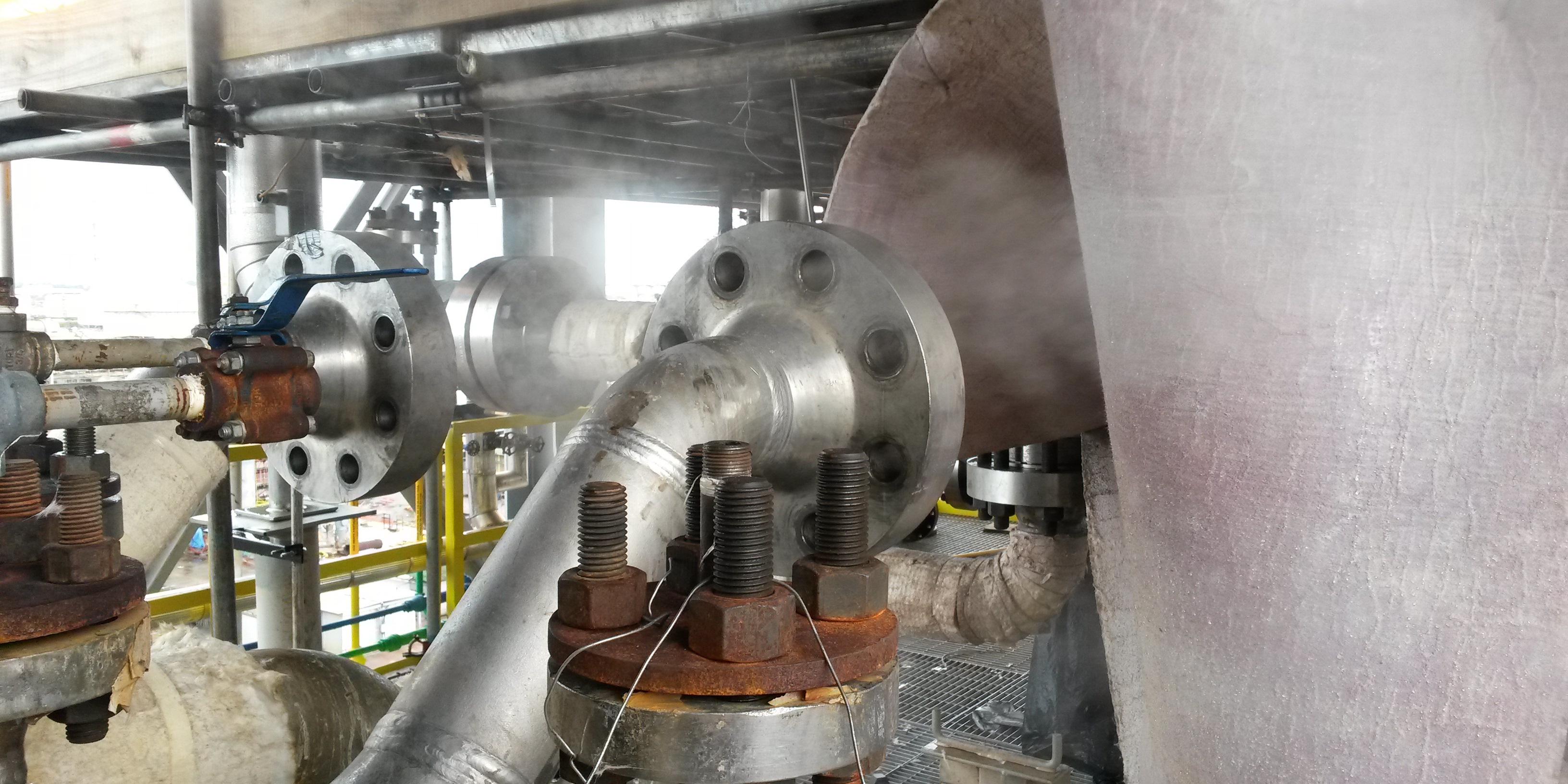

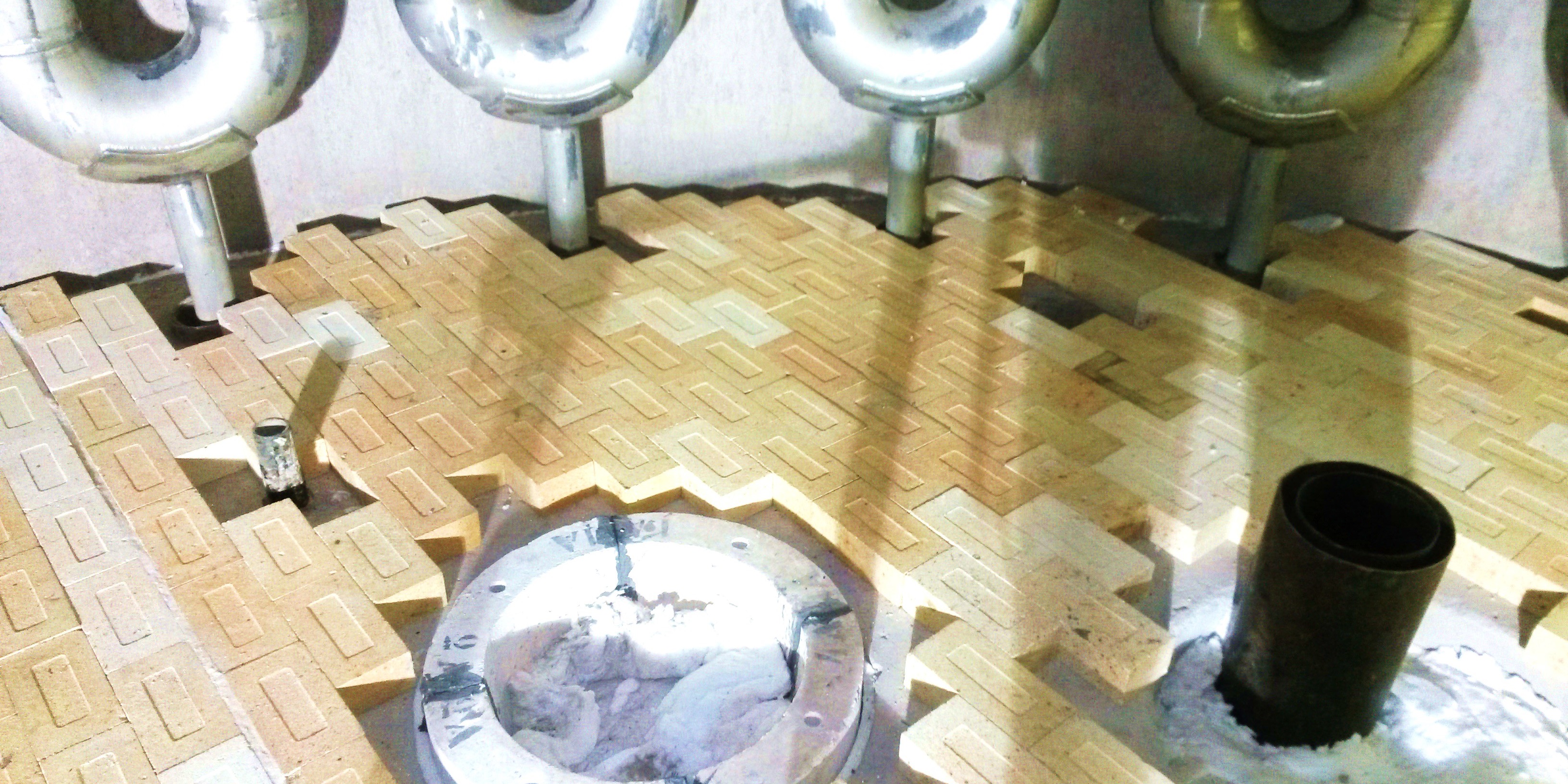

Drying of refractory lining

We have extensive experience in the execution of thermal services, with a history of over 10,000 heating services in plants of various segments throughout South America, Central America and the Caribbean.

We perform the drying and heating of refractories with portable burners, which can be positioned in the most diverse regions of the target equipment. As a result, there is a distributed supply of combustion products, with high thermal uniformity and agility in raising temperatures and removing moisture.

These characteristics meet demands for thermal input at the start or resumption of operation of the most diverse equipment.

Particularly in the Fluid Catalytic Cracking (FCC) units, our performance contributes to accelerate the schedules for starting or resumption of the operation, with sooner production.

In addition to heating and drying, we operate in stress relieving, accelerated or controlled cooling, expansion control and other various modalities of application of Thermal Engineering to tailor-made projects.

Featured

- Drying of cyclones at a plant for 323 thousand barrels of oil per day

- Drying of process furnaces at a plant for 230,000 barrels of oil per day

- Drying and heating for starting-up the Fluid Catalytic Cracking (FCC) units at a plant with capacity of 178 thousand barrels of oil / day