GLASS

Heating, cullet filling and expansion control

We have equipment and qualified personnel for the design, planning and execution of all support services at the start and restart of the furnace.

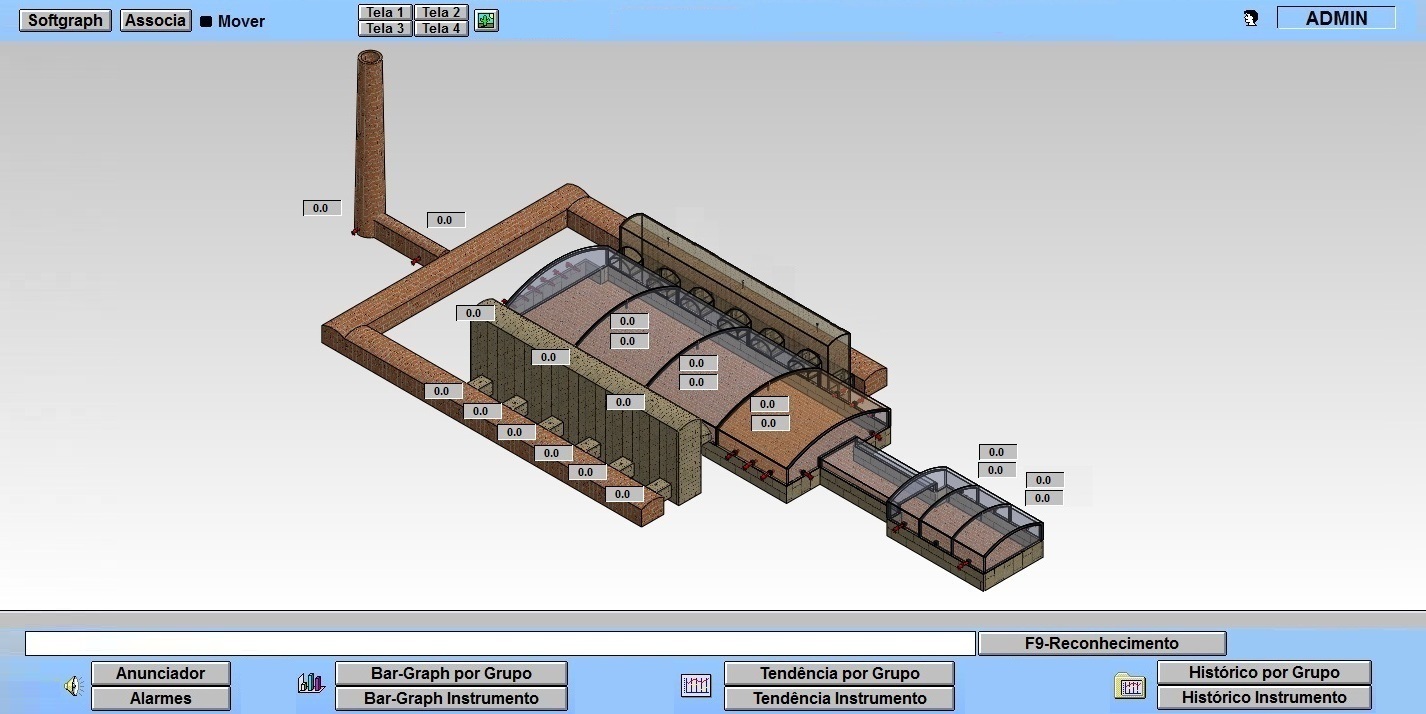

In the same way as for the cooling operations, during heating our burners blow into the furnace large amounts of hot gas. This characteristic promotes the thermal uniformity of the furnace over wide extensions, which we follow by measuring the temperature equalization between the different regions: melting, refining, regenerators, feeders and exhaustion. Our equipment also allows us to accurately follow the programmed heating curves, executing light slope temperature ramps, up to 1°C/h.

We study the filling programs and, with our own cullet feeder and specialized teams, we deliver cullet to the furnace at the planned rates. During this process, we operate the burners necessary to conserve the needed temperature at the refining zone, at the level demanded by the process.

With a technical staff of around 40 years of experience, we carry out from the elaboration of the predicted curves of expansion to the installation of instruments and reading of expansion levels, with execution of the adjustment of tie rods and pushers.

Full support to starting-up

We have equipment and specialized teams to conduct all the steps with safety and control:

- Heating

- Cullet filling

- Expansion control

Featured

We performed the heating and cullet filling at the start-up, in addition to draining and filling services, cooling, expansion and contraction control, and heating, in maintenance stops at a float glass plant:

- 19.2 m² Jumbo Mirror production unit

- Furnace with capacity of 70,000 tons per year