Non-ferrous

Temperature variation or hot-hold with efficiency and agility

We operate in non-ferrous plants in the execution of activities such as cooling, thermal comfort, controlled drying and heating of refractory linings.

In the aluminium industry, we provide thermal services to primary metal suppliers and to recycling companies, with solutions to fluidized bed furnaces, casting furnaces, holding furnaces, troughs and crucibles.

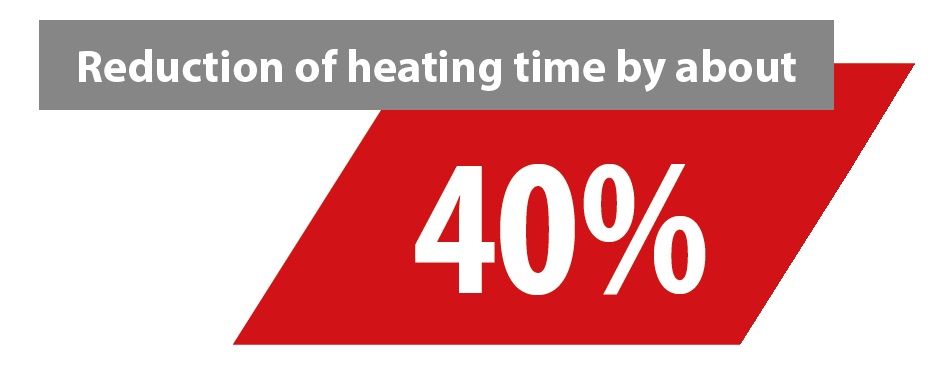

In the nickel industry, we operate at the start-up of units, general and partial renovations of rotary kilns for calcination, electric furnaces, containers for calcined and ladles. In an innovative and pioneering performance in Brazil, we performed the initial heating with the simultaneous use of external burners and process electrodes. Thermojet burners allowed to equalize temperatures, attenuate the mechanical stress in the refractory and reduce the heating time by about 40% compared to the conventional process.

In the copper segment, we perform services in various equipment, especially converters, flash furnaces, electric arc and induction furnaces.

We have a dedicated technology development division, Æstus, and we partner with research institutions, as well as invest in tools such as heat transfer simulation software, to always deliver sustainable, high-performance, innovative solutions in products and services of Thermal Engineering.

Equipment served

We have experience in Thermal Engineering applied to the most diverse types of equipment in the non-ferrous industry:

- Rotary furnace

- Recycling furnace

- Holding furnace

- Casting furnace

- Side well furnace

- Crucible, among others

Featured

- Drying and heating of aluminium casting furnaces with capacity of 80 tons

- cooling, thermal comfort and heating of calcination unit at a plant with a production capacity of 466 thousand tons/year

- Initial heating of an electric furnace at a plant with capacity of 9,000 tons of nickel per year, reducing the heating time by 40%