Mining and pelletizing

Innovation in favour of agility

We offer solutions for various areas of mining and pelletizing plants, and we develop joint computer simulation work for optimized drying curves. Our experience from drying and heating to cooling and thermal comfort in the most diverse equipment:

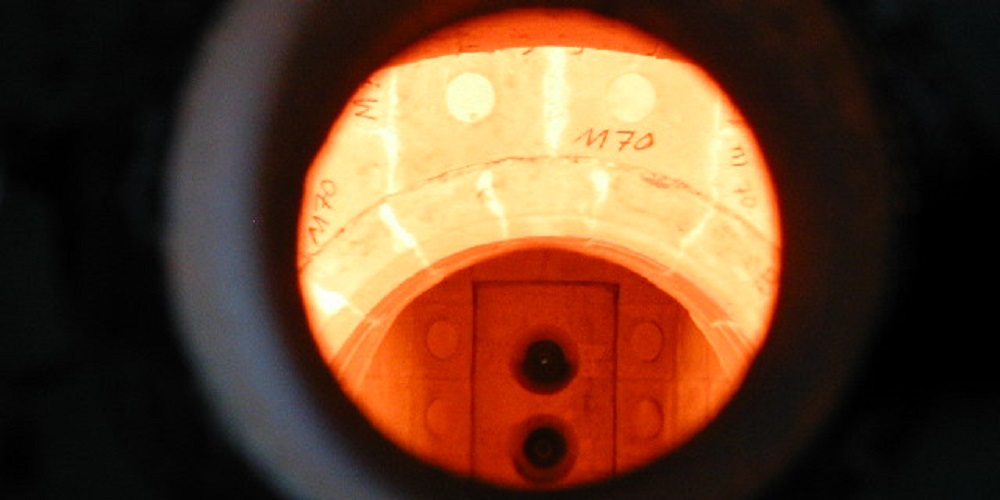

Specifically for pelletizing furnaces, uniform heating in all chambers is important and challenging. With a division dedicated to the development of technology, Æstus, we developed a method that allowed 50% reduction of downtime. We are proud that our method is today applied to the largest pelletizing units in the world.

Quanto às operações de resfriamento, desenvolvemos, numa operação específica, procedimento que resultou numa redução de mais de 24 horas no tempo de resfriamento, com relação ao método habitualmente praticado.

Equipment served

We have extensive experience in Thermal Engineering applied to the most diverse types of equipment for mining and pelletizing:

- Pelletizing furnaces

- Dryers

- Calciners

- Electric reduction furnaces, among others

Featured

- Heating for start-up and maintenance of the electric furnace and calciners at one of the largest iron-nickel plants in the world, with a production capacity of 220,000 tons per year

- Heating for start-up and maintenance of an electric furnace with capacity of 165 tonnes of dry ore per hour and calciners with a length of 185 metres and capacity of 250 tons of ore per hour

- Cooling, thermal comfort and heating services at plants of the world's largest pelletizing pole, with a pellet production capacity of 36.2 million tons per year