COBRA

High availability with resource saving

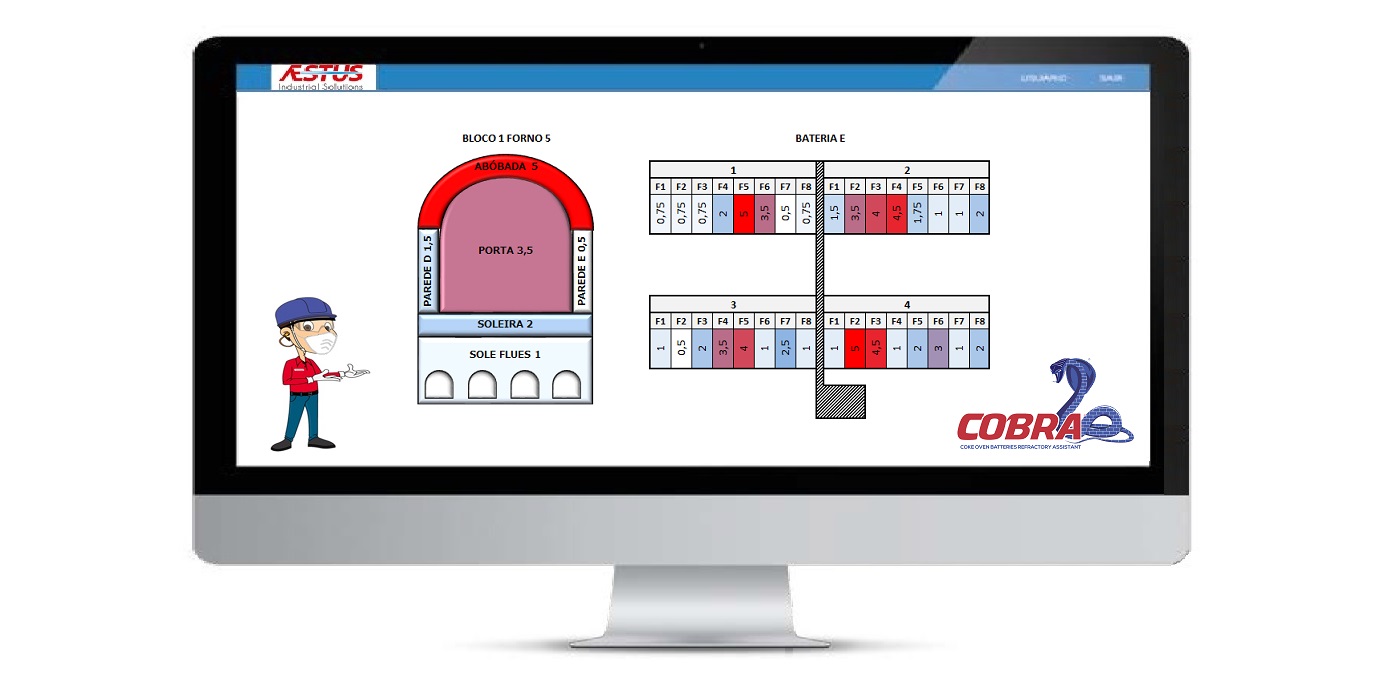

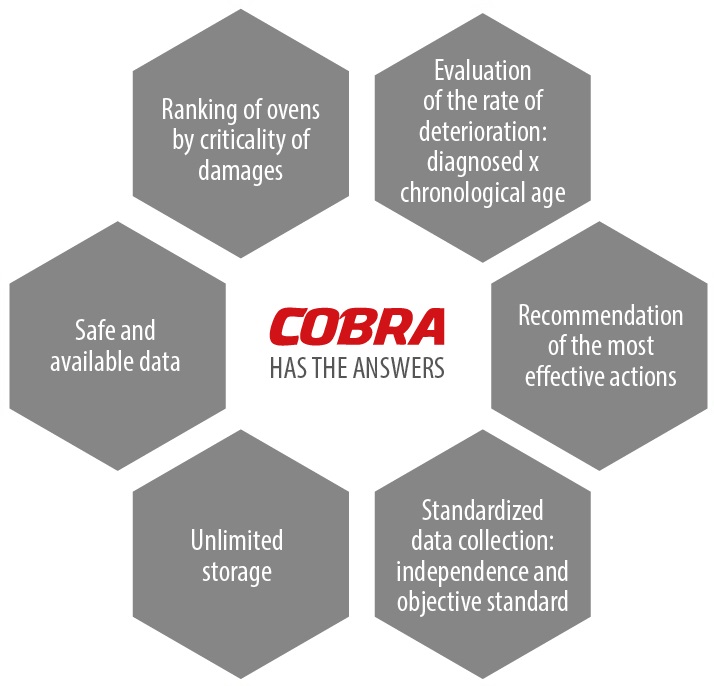

Developed by our technology division, Æstus, and named from the acronym Coke Oven Batteries Refractory Assistant, COBRA software organizes and processes the large volume of data obtained in Refractive Diagnosis.

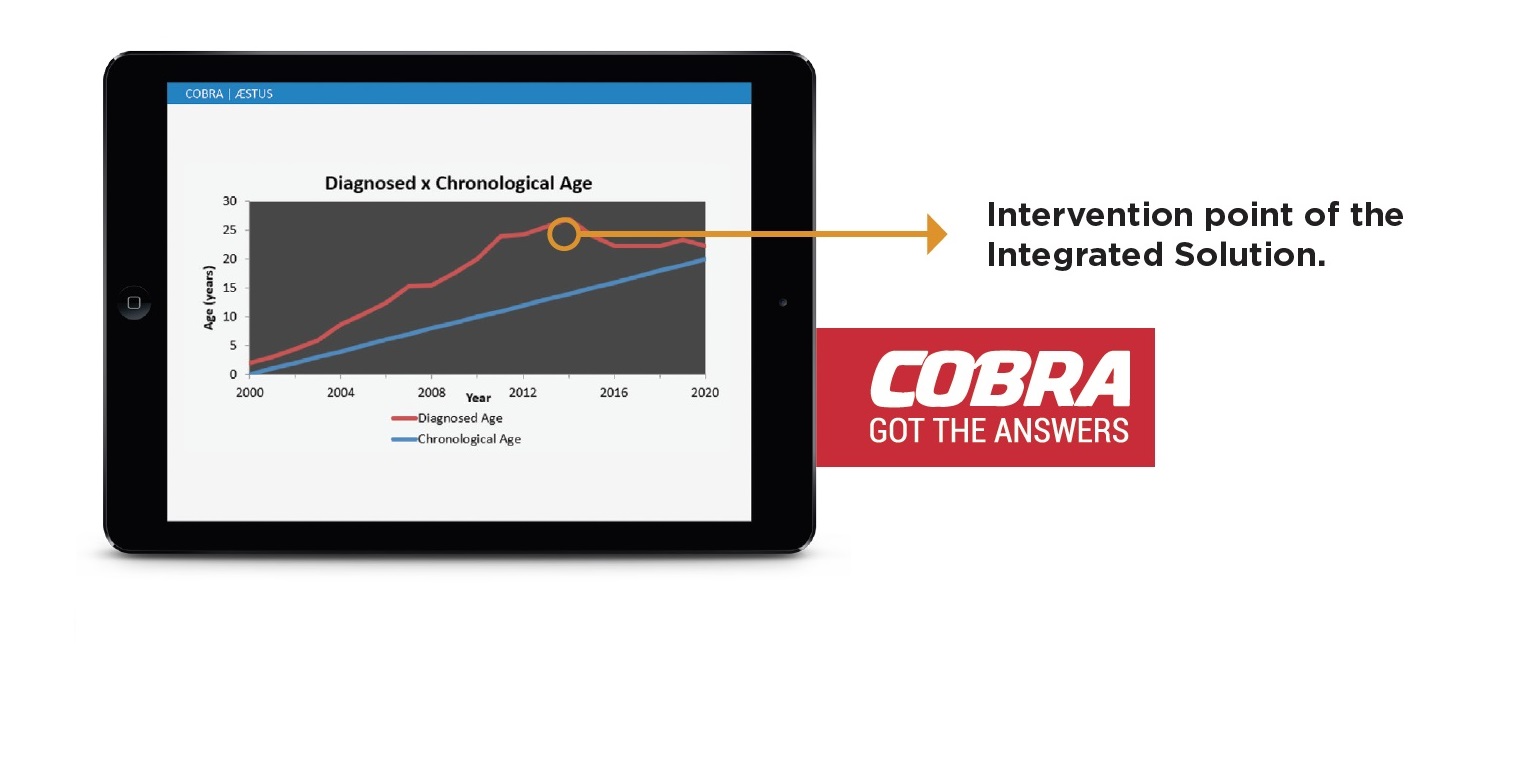

Its periodical infographic reports allow for the agile interpretation and systematic identification of the most critical regions, to rationalize the use of maintenance resources. Preservation plans point to corrective and preventive actions recommended to maximize the life of refractory lining with efficient use of material and labour.

FEATURED

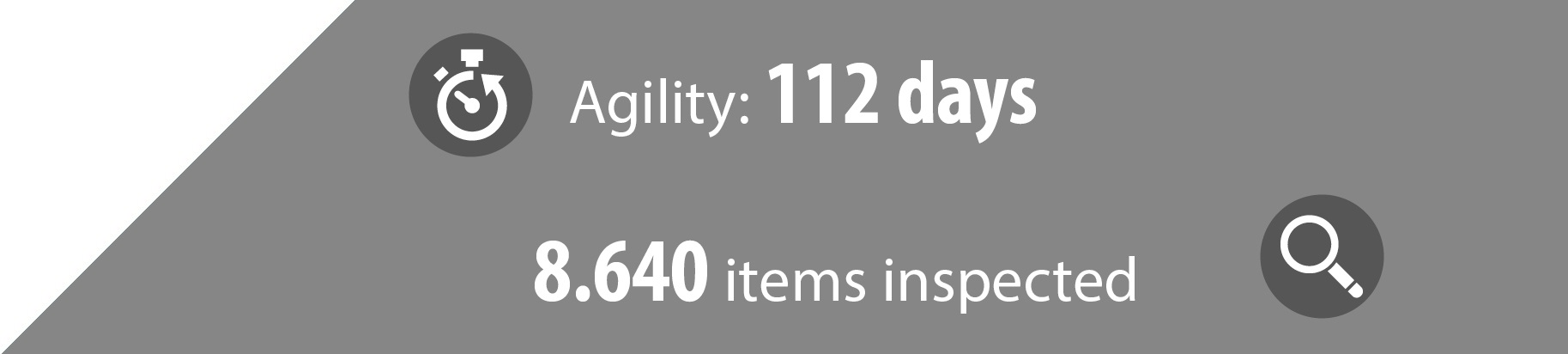

We performed Refractory Diagnosis with the software COBRA at heat-recovery coke oven batteries. During the project, executed with high daily inspection rate, more than 4,500 photos and almost 300 high resolution videos were obtained, combining technical photography and endoscopy.

The results were recorded on about 900 inspection maps, and organized and handled by the software COBRA, which has a big data tool for quick interpretation.

INTEGRATED SOLUTIONS FOR MANAGING THE LINING OF COKE OVEN BATTERIES

- Refractory Diagnosis

- COBRA Management

- Jetwelding® ceramic welding

In a project executed with Thermojet package of Coke Battery Refractory Management solutions, a potential gain of up to 10 years of preserved life was estimated. The work, "Refractory Maintenance of Coke Oven Batteries", was presented at the 46th Reduction Seminar, ABM Week 2016 .